SERVICES AND SUPPORT

Services And Support

EURO-CNC provides on-site machine field service repair throughout the Finland. Our usual response time to service is about 6/24 hours. A machine that is ‘down’ is a problem that needs solutions as quickly as possible. Reduced productivity, decreased capacity, and revenue lost. It is paramount that you get prompt, expert service to diagnose and fix the problem!

- Work on Any Make/Any Model of CNC Machinery

- Machine Tool Evaluation/Inspection

- On-Site CNC Machin Service and Parts replacement

- Control /drives /electronic system fine-tuning & troubleshooting

- Mechanical /hydraulic /pneumatic repairs

- Alignment/Leveling Systems

- Including: Rotalign, Boralign, and P-Level

Whether machine repairs are made at your location or back at our shop, our knowledgeable, experienced service technicians will troubleshoot what is wrong, provide a plan, and make the repairs needed to get you up and running again.

CNC Machine

- Horizontal Boring Milling

- Horizontal Machining Centers

- Floor type Horizontal Boring Machines

- Vertical Machining Centers

- Multi-Axis (B-Axis) Turning Centers

- 5-Axis Machining Centers

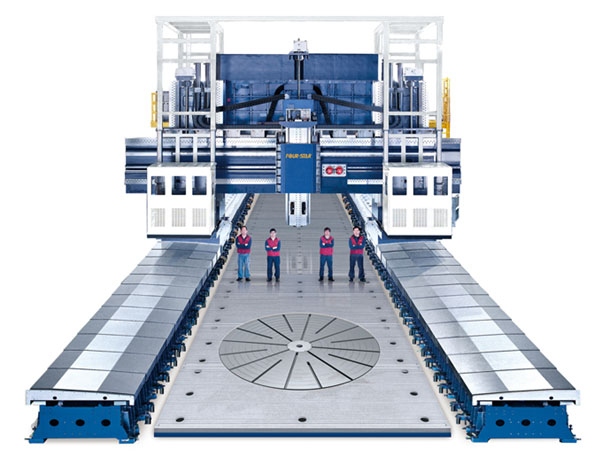

- Bridge and Gantry Milling

- Multi Spindle Turning Centers

- Double Column Machining Centers

- Universal Milling Machines (5-Axis)

- CNC Lathes, Turret Lathes, Milling, VTL’s

- Laser/Plasma Cutting Machines

- Water Jet Machines

- Hobbers Machines

- Press Machine and Turret Punch Press Machines

- Welding Machines

- Overhead Cranes

- Conventional and Special Purpose Machine

CNC Controls Repair

- Fanuc All Series

- Heidenhain All Series

- Siemens All Series

- HAAS All Series

- Mazak All Series

- Mitsubishi Series

- Yaskawa Yasnac

- Bystronic Laser

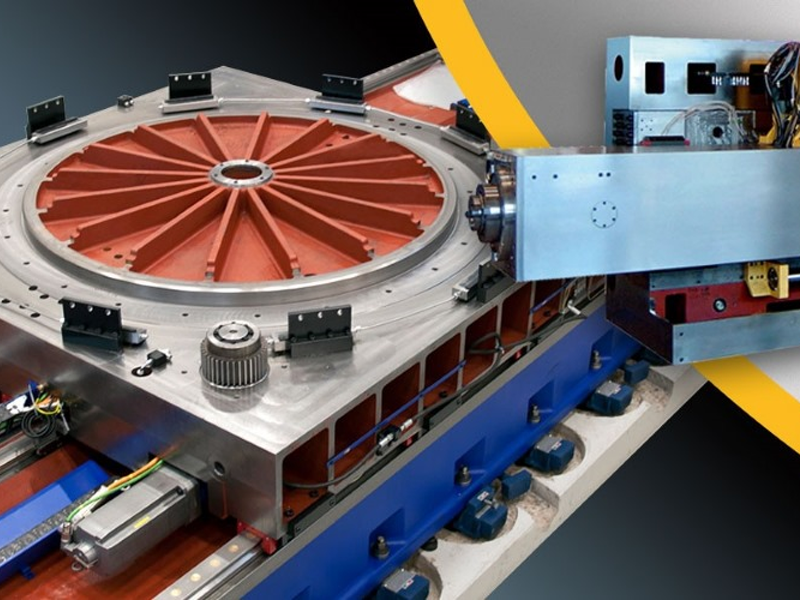

Machine tool rebuilding involves a detailed process to assess, measure, dismantle, catalog, research, scrape, grind, paint, fit, align, and test run. Hydraulics, pneumatics, electrical, mechanical, safety – all aspects of machine operation come under the highest levels of examination to insure like-new performance and accuracy.

You can rely on EURO-CNC to get your machine tool rebuild job done right—on time and on budget:

- Complete machine tool disassembly/reassembly

- Way Work (including scraping, alignment, and linear way replacement)

- Expert part reconditioning and/or, machining, rebuilding, sourcing

- Work-holding Chuck and Hydraulic cylinder repair and replacement

- Ball Screw Repair and Bearing Replacement

- Linear Guideways and Liner Bearing Replacement

- Box Guideways Hand Scraping and Gib Preload Adjustment

- Motor repair and replacement

- Spindle Repair and Rebuild

- Spindle Drawbar Repair and Bearing Replacement

- Gear Box Repair and replace the New Parts

- Telescopic guideway Cover, Bellow Covers Repair and change the Wiper Lips

- Drives Upgrades and Modify the Electrical PLC Wiring

- Hydraulic Unit Repair and replace the New Parts

Machine tool retrofits most often go hand in hand with machine repair or rebuild projects. A CNC Control Retrofit empowers good old machines to do even more, with additional functionality and restored reliability.

Retrofits & Modifications

Specifically designed for your machine, our retrofit solutions help:

- Improve productivity

- Expand capabilities

- Energy savings

- Extend machinery life

- Assure machine safety

Whole machine assessment (Mechanical, Electrical, Hydraulic, Pneumatic)

- PLC panel building and re-wiring

- Complete retrofit integration

- Follow-up training and documentation (if requested)

Retrofit solutions that improve reliability and productivity and prolong machine life are obvious ways to achieve bottom line improvements. But the possibilities go far beyond that. Expanding the capabilities of your machines will open doors to new applications and business without investing in new equipment.

EURO-CNC repair all makes and models of AC Drives, DC Drives, Power Supplies, Servo Amps. Plus, Position Encoder all makes and models of VFDs, SCR Power Controls, Touch Screens, Temperature Controllers, Timers, Motion Controllers, Process Controllers, Stepper Controllers, Counters, PLCs, HMIs, I/O Modules, All Electrical & Electronic equipment repair and replace the parts.

We also repair industrial monitor, look no further than EURO-CNC. Monitors are the eyes of your operation, and we can make sure that you are seeing clearly all the time. Everyone can agree that cathode ray tube technology is a trend of the past. LCD, LED, Plasma and HD displays have superseded this type of technology. This outdated technology is used by companies whose older equipment have CRT monitors that still work and people who like playing vintage video games on the screens they were intended for originally.

PTR knows that old tech becomes obsolete tech, and obsolete can mean a major issue if you are down. There’s no cause for concern if you are still using machines with CRT monitors, EURO-CNC has Engineers that have been in the electronics business for decades, and are familiar with CRT technology, allowing us to repair, refurbish and recondition any CRT Monitor that you may have.

A CNC machine is a finely crafted tool that needs correct alignment to function at its best. When a machine is not properly calibrated, the end product may have deformities, or the dimensions may be wrong. Even worse, a machine that is perpetually run out of alignment will have a shorter lifespan.

This is especially relevant if you’ve experienced a crash. After a machine crashes, you can expect four common problems:

- Machine moving axis backlash and repeatability may be lost.

- Spindle runout, ATC arm position, Turret tool position may be lost.

- Rotary home positions may be lost.

- The bridge position on the columns may shift.

- The XYZ position on the bearings may shift.

- LM Guideway may be pushed out of alignment.

To have confidence in your end product, calibration is key. Diversified Machine Systems (DMS) has a team of experts that routinely goes on-site to calibrate our machines throughout the nation—but we’d rather train you to become the expert instead. With the proper training, you’ll know how to “look under the hood” of your machine and calibrate it with confidence.

In this blog, we’ll walk you through all five axis alignments for a highly functioning machine. We’ll help you master the elements of linear squaring, which will incorporate all three primary relationships of Perpendicularity—XY, XZ, and YZ.

As you get started, we recommend several tools. A machinist’s level, sweep indicator, sweep arm, plunge indicator, mag base, tooling ball, and dowel pin are all useful to have on hand. DMS is happy to provide any of these tools to you at a fair price.

Squaring a machine involves an exact order of operations. Steps one through five must be completed in their given order; otherwise, you risk negating a previous step.

1. Level The Base

Before you begin to work on your machine, you’ll want to establish a level base. The consequences of a non-level platform are manifold: rails, bearing blocks, and base weldments will all suffer excessive stress. Repeatability becomes impossible, and you may require replacement parts.

To level your base, use a three-plane laser or machinist’s level on the bridge rails and base rails at multiple fixed points to make sure the machine is aligned. In doing so, you create a level plane along the linear rails that are attached to the base of the machine. Although it is not necessary, we recommend that the plane should be earth-level for ease of use.

2. Square The Bridge (X-to-Y)

Once you have a level base, the bridge needs to be square. This will involve creating a perpendicular axis between X and Y, where X is the bridge transverse travel and Y is the moving table or moving gantry. You will shift the fixed X axis in relation to Y.

To adjust the bridge, start with the six mounting bolts. Keep the lower right bolt tight as a pivot point and remove the upper left bolt completely. Then loosen the remaining four bolts. Using a mag base and a dial indicator, you can then check the alignment of the bridge.

Attach the mag base to the spindle or the spindle yoke, and then move it to one side of your table and zero out the indicator. From there, move across the front of the table and watch for a linear deviation. If such a deviation exists, you can assume that the bridge is not square. Using the indicator, you can re-align the bridge and then replace the six bolts.

3. Square The Backbone Front-To-Back (Z-to-Y)

Next, you will square the backbone front-to-back. It may be tempting to shim the backbone to the Z rails, but that would not square any problems. Instead, shim the whole backbone carriage between the bridge rails. You can use a laser or granite blocks for this step. Align the granite to the Y plane and then indicate off of the 90-degree granite edge. Make shim adjustments as necessary to make the Z axis perpendicular to the Y.

4. Square The Backbone Side-To-Side (Z-to-X)

You will now square the backbone side-to-side, where Z is perpendicular to the bridge. Repeat the previous step, indicating off of the side instead of the base. Shift the backbone by leaving one of 16 bolts tight as a pivot point. Place an adjustment wedge on the right or left side, creating a wedge between the backbone and the top of the running block. Using the indicator, adjust until the Z-to-X is square.

5. 4th Axis And 5th Axis Alignment

The fourth and fifth alignment are the most complex. On a EURO-CNC the fourth axis is the C axis, which rotates around Z. The fifth is the spindle rotation, which can be an A axis (which rotates around X) or a B axis (which rotates around Y). Because these alignments are more complex.

In the event of a crash, the Z rails are more likely than the bridge rails to bend out of alignment. They are also the most challenging to straighten again. If your Z rails are out of alignment, we invite you to call a EURO-CNC expert to come align it for you.

To straighten a bridge rail, pull off a bearing and attach the mag base and plunge indicator. Zero the indicator and then begin to move it along the rail. Mark every place where the indicator reveals that the rail is out of square, and then loosen all the bolts in that window. One-by-one, push or pull on the rail using a pry bar and zero out your indicator, re-tightening each bolt as you straighten the rail. Continue systematically along the entire rail until it is square.

With these five steps of calibration, you can find and fix most calibration problems with a few tools and some newfound expertise. And of course, EURO-CNC is always happy to help by providing further instruction or by sending a specialist to assist you onsite.

EURO-CNC can provide a full handling and logistics service if you need to move equipment from one place to another, from manufacturer to your company, reorganize your workshop, or remove outdated equipment. We also make sure that all relocated and re-commissioned machinery are thoroughly inspected for level, geometry, and proper operation. EURO-CNC has years of experience moving machine tools. EURO-CNC has handling all types of cnc machines other factory equipment.

We are fully trained and qualified in Heidenhain maintenance servicing and repairs and also specialize in new, exchanged and repaired. when there are troubles with an encoder’s operation if you want assist contact EURO-CNC we can solve your problems start-up your machine less downtime, our engineers can repair your problem Encoders Angle encoders, Rotary encoders, Linear encoders, Digital readouts and interfaces, ESR strain sensor, it is advisable to check the mechanical and environmental factors before troubleshooting it, other environmental issues. Basic checks like checking the input voltage and the wiring connections must be done before going to the next steps in troubleshooting. We are check below mention the points for your measuring instrument.

- Cleaning and Repairing of Linear Encoders scale

- Encoder Jitter

- Signal Flicker

- Extended Encoder Pulses

- Low Amplitude Signals

- Shark Fin Pulses

- Stepped Encoder Pulses

Depending on the source of supply, the lead time for ordering spare parts might range from a few moments to many months. When using imported equipment, this issue is serious. EURO-CNC provide industrial customers a range of affordable choices for managing their supply chains for end-to-end maintenance, repair, and operations in a market that is becoming more and more competitive.

While continuously working to reduce total procurement costs, ensuring that we adhere to the highest standards of quality assurance, and guaranteeing on-time delivery of the components, we offer an integrated set of spare parts procurement services. All of our contracts and models are made to order utilizing cutting-edge information technology that is compatible with any enterprise resource planning system, encompassing the complete flow from order to delivery.

CNC software refers to the computer tools used to build programs for CNC machines. The software combines software, equipment, processes, and people to develop and build high-quality items on time and accurately. It is capable of doing more than merely controlling CNC machines on a work floor. Finally, CAM software allows anyone to build programs for a range of CNC machines to support various manufacturing processes. EURO-CNC have experience with a variety of applications and can help you upgrade them.

We also connect the controlled machines to the internet via WLAN and traditional wired data lines. Older control connections can also be converted to wireless connections. Modern wireless data connections are less expensive to install than traditional technologies. New base stations are also simple to integrate into the network. Both types of technologies are compatible with your organization's existing information network.