PREVENTIVE MAINTENANCE

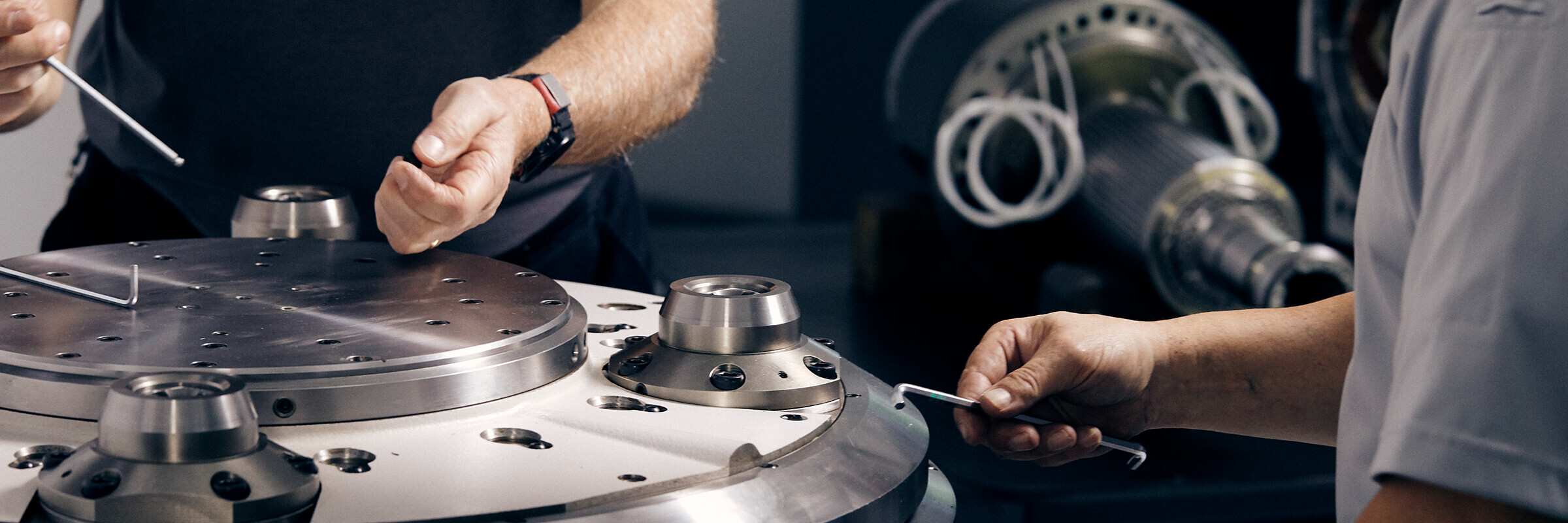

Complete Maintenance Solution

Whether you have an existing preventative maintenance program or need one developed, our team of experts will review your current processes to collect, examine and leverage data to identify the changes necessary for increased uptime in your facility. Then our maintenance Engineer will get to work, executing your preventative maintenance plan (PMP) and delivering measurable results.

- Experienced preventive maintenance Engineer

- Program service for CNC Machine and Manual Machines

- Controller /drives /Motors/ Encoder/ Electronic system fine-tuning & troubleshooting

- Inspection of drives, power supply, I/O cards, motors, belts, pulleys

- Electronics connection checks to include voltages, amperages

- Tightness verification for bolts, screws

- Operating controls and safety controls during each visit

- Inspection of sensors and position encoder

- Mechanical /hydraulic /pneumatic repairs

- Cooling system flush and clean service

- Precision levelling & alignment all moving mechanical parts

- Ball bar analysis (tests accuracy and repeatability of your machine tool)

- Vibration analyser

Preventative maintenance can also include (but is not limited to) the following:

- Check automatic tool changer alignments

- Check automatic pallet changer alignments

- Change CNC control backup batteries

- Ball screws and end bearing checks

- Gib and slide, LM Guideway and LM Bearing checks/Way wiper checks

- Check axis backlash

- Change the Gear box Cooling fluids

- Clean all filters and replace new filters

- Check the Hydraulic and Pneumatic valve, Hose pipe conditions

- Check the all input and output sensor conditions

- Check the chip conveyor bearing rollers condition replace the new parts

- Inspection of alignment and verifications of all axes (this is not an squaring alignment but a verification to see if an alignment is needed; 5-axis PMP plans do include a head alignment (4th & 5th axis only) Inspect lubrication systems, fluid levels

- General machine maintenance advisories and training

- Time allowing, any specific training or machine operation, based on customer needs

- Identification of current or potential issues; once the full PM has been completed the technician can discuss future corrective action recommendations and options.

From aerospace to automotive, machining to manufacturing and just about every industry in-between, our highly cost-effective machine tool repair & support services are tailored to your needs with dedicated Mechanical, Electrical and Software engineers who can provide the best maintenance solution for you.

An Annual Plan Or Semi-Annual Plan Or Quarterly Plan

A Preventive Maintenance Program offers a permanent record of the machine maintenance history and its current state in addition to lowering wear and almost eliminating emergency breakdowns. Through planned maintenance, you may arrange machine downtime as opposed to having it schedule you. Preventive Maintenance is one of the many machine tool services that EURO-CNC provides, unfortunately, most people choose to ignore it. According to studies, a preventive maintenance program results in significant cost savings for machine tool repairs and greater production because there is less downtime.

EURO-CNC can create a preventive maintenance program just for you. We can assist you in creating, organizing, and carrying out the full program, whether you're searching for an annual or semi-annual plan or quarterly plan. EURO-CNC is dedicated to providing our customers with exceptional scheduled maintenance, and we want to establish long-term partnerships by assisting with current difficulties and long-term planning.